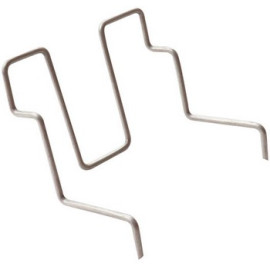

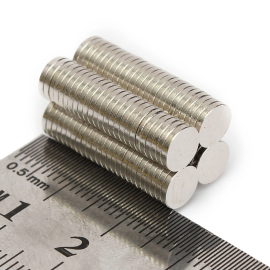

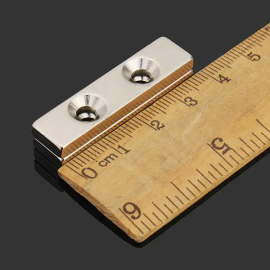

Production of springs on CNC machines

Here is the shipping cost. You can choose any of the available shipping methods when placing an order.

- Automobile transport

- CCTV

- Development software

- Medical equipment

- Spare parts for repairing household appliances

- Spare parts for repairing laptops and computers

- Spare parts for repairing smartphones and tablets

- Toners for printing devices

- TV repair parts

- Water dispensers

- Automobiles, buses

- Motics

- Bicycle technology

- Spare parts for cars, motorcycles

-

Electronics

- Smart watch

- WiFi Routers

- Electronic components

- Boards, modules

- Measuring instruments

- Kits and Constructors

- Electronics Tools

- Laptop Parts

- Tablet spare parts

- Smartphone spare parts

- Sensors

- Antennas

- Radio components

- Power supplies

- Batteries

- Displays

- Control units

- Relays, timers

- Enclosures for electronics

- Gadgets

- Home electronics

- Car electronics

- Computer technology

- Construction and repair

- Hand tools

- Home appliances

- Household products

- Garden

- Men's clothing

- Women's clothing

- Children's clothing

- Men's shoes

- Women's shoes

- Children's shoes

- Furniture

- Kids toys

- Gifts

- Animal world

- Construction machinery

- Agricultural machinery

- Production equipment

- Spare parts for machinery

- Municipal vehicles

- Water transport

- Air Transport

- Railway transport

- Food

Your shopping cart is empty!

Related Products

Arduino Mega2560 USB board

Drone

Product Description

We produce any springs on CNC machines. We use Haas 5-axis high-tech machining centers with 360 degrees of rotation for machining. You can send us a drawing for a quote if you have a CNC machining project or our engineers will prepare a turnkey product for you, from idea to finished product.

To order, contact us in any convenient way. Our factory is located in China, Shenzhen. We have representative offices in Russia and Belarus, we invite you to visit our production in China. We also have representative offices in Western Europe - in Germany and Poland.

Our machines drill, mill, grind, cut in any plane with high precision. We do priming and painting products. CNC milling is a special form of numerical control (CNC) machining. Milling itself is a machining process similar to drilling and cutting and allows you to perform many of the operations performed on cutting and drilling machines. Like drilling, milling uses a rotating cylindrical cutting tool. However, a cutter in a milling machine is capable of moving in multiple axes and can create various shapes, slots, and holes. In addition, the workpiece often moves across the cutter in different directions, as opposed to the movement of the drill in one axis.

Product shearing processes are processes in which a piece of sheet metal is sheared off using enough force to break the material. The most common cutting processes are performed using shear forces, which is why they are sometimes referred to as shear processes.

When a sufficiently high shear force is applied, the shear stress in the material will exceed the shear strength and the material will break and delaminate at the cut. This shear force is applied by two tools, one above and one below the sheet. Whether these tools are punch and die or top and bottom blades, the tool above the sheet delivers a quick downward strike against the sheet metal lying above the bottom tool. There is a small gap between the edges of the upper and lower incisors, which facilitates the destruction of the material. The size of this gap is typically 2-10% of the material thickness and depends on several factors such as the particular cutting process, material and plate thickness. Shear effects on the material change as the cut progresses and are visible at the edge of the cut material. When the punch or blade strikes the sheet, the gap between the tools allows the sheet to plastically deform and "flip" the edge. As the tool penetrates further into the sheet, the cutting results in a vertical polished area of the material. Finally, the shear stress is too high and the material breaks at an angle with a slight burr on the edge. The height of each of these parts of the cut depends on several factors, including the sharpness of the instruments and the gap between the instruments.

CNC machining centers are being used to produce a wide variety of components, and the associated tooling costs continue to become more affordable. In general, large production runs requiring relatively simple designs are better served by other methods, although CNC machining can now satisfy a wide range of manufacturing needs. CNC milling centers are the ideal solution for everything from prototyping and small-scale production of complex parts to the manufacture of unique precision components.

You will feel ease and comfort in communication and work if you cooperate with us.

When you order from opencartworks.com, you will receive a confirmation email. Once your order is shipped, you will be emailed the tracking information for your order's shipment. You can choose your preferred shipping method on the Order Information page during the checkout process.

The total time it takes to receive your order is shown below:

The total delivery time is calculated from the time your order is placed until the time it is delivered to you. Total delivery time is broken down into processing time and shipping time.

Processing time: The time it takes to prepare your item(s) to ship from our warehouse. This includes preparing your items, performing quality checks, and packing for shipment.

Shipping time: The time for your item(s) to tarvel from our warehouse to your destination.

Shipping from your local warehouse is significantly faster. Some charges may apply.

In addition, the transit time depends on where you're located and where your package comes from. If you want to know more information, please contact the customer service. We will settle your problem as soon as possible. Enjoy shopping!